State departments of transportation across of the country are looking at new and better ways to predict traffic noise levels, as well new materials for highway sound barriers, in order to reduce the overall cost of noise abatement efforts.

[Photo courtesy of the Ohio Department of Transportation.]

The first article of this two-part series will examine some of the new tools state DOTs are developing to better gauge the impact of noise on communities near transportation infrastructure such as highways.

First, some background: According to the noise barrier inventory maintained by the Federal Highway Administration, more than 3,000 linear miles of noise wall barriers have been built since the 1970s across the United States.

Such sound barriers remain an essential part of highway design and construction as the World Health Organization determined that prolonged exposure to high levels of noise “interferes with people’s daily activities … disturbs sleep, causes cardiovascular and psychophysiological effects, reduces performance and provokes annoyance responses and changes in social behavior.”

Photo courtesy of the Iowa Department of Transportation

The Noise Pollution and Abatement Act of 1972 requires state departments of transportation to monitor and manage highway traffic noise generated by federally funded projects on existing and planned roadways. When that sound exceeds certain thresholds, 23 CFR 772 specifies mitigation efforts must be undertaken to reduce highway traffic noise.

Yet the cost of meeting those regulations and protecting the public against the roar of the vehicles — the predominant sound for both cars and trucks is that of tire-pavement interaction – takes considerable funding.

For example, between 2014 and 2016, FHWA found that total construction costs for noise barriers topped $671 million in just a three-year period – an average of $2 million per mile of noise wall.

That’s why many state DOTs are trying to find ways to reduce the cost of noise abatement efforts, noted Noel Alcala.

“The main goal of more accurate noise abatement modeling can result in cost reduction,” explained Alcala, the noise and air quality coordinator at the Ohio Department of Transportation and noise work group coordinator on behalf of the American Association of State Highway and Transportation Officials, in an interview. “Modeling noise levels more accurately can likely reduce costs noise wall in construction.”

States currently use the FHWA Traffic Noise Model 2.5 to predict noise levels that will occur once a road is built or expanded – even if that expansion occurs several decades in the future.

That complex formula includes the mixture of cars and trucks expected on the road; the buildings and vegetation in the area that would block some sound; the configuration and ground quality of the land between the road and the homes; the ways the sound is expected to diffract around the wall; and other key factors. Other weather factors can also play a role, such as wind direction and ground and air temperatures. Also considered is the height where the noise is actually originating – at roadway level or top of truck stacks.

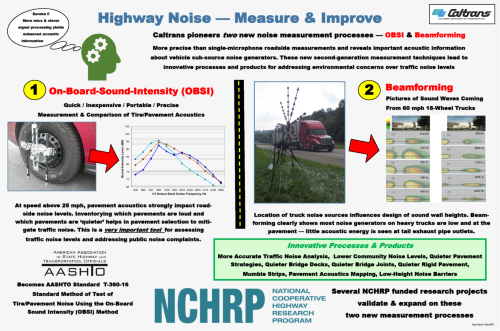

Courtesy of Caltrans

The overall goal of some states, such as California – which sports over 750 miles of highway sound walls – is lowering the noise level at the transportation infrastructure source – a far-cheaper effort than blocking the noise with a more expensive sound wall.

To that end, the California Department of Transportation has worked over the last few years to implement the most recent National Cooperative Highway Research Program or NCHRP findings into newer modeling techniques.

Caltrans relied on documents such as NCHRP Report 635: Acoustic Beamforming: Mapping Sources of Truck Noise, which experimentally validated a practical acoustic “beamforming” measurement technique.

“Beamforming” uses a type of camera that takes pictures (or video) of soundwaves and illustrates that very little acoustic energy comes from tall truck exhaust stacks. Meanwhile, it shows that most highway noise is tire/pavement related and usually occurs very close to the pavement.

NCHRP Project 1-44, reported in NCHRP Report 630, also proved valuable to Caltrans efforts as it proposing a test method for measuring tire-pavement noise at the source using the on-board sound intensity (OBSI) method.

The agency also is implementing AASHTO T 360-16 (2020) – the Standard Method of Test for Measurement of Tire/Pavement Noise Using the On-Board Sound Intensity (OBSI) Method – to reevaluate noise modeling efforts and improve modeling to provide more accurate results. Caltrans has also moved to use more precise noise measurement processes, which it believes will lead to lower community noise levels.

“The AASHTO Standard which precisely measures pavement acoustics, allowed a lot of this work to be accomplished, explained Bruce Rymer, senior engineer in the Hazardous Waste, Air, Noise, & Paleontology Office within Caltrans.

“Using this new measurement technology, we found pavement acoustics had a much larger influence on roadside noise levels than previously acknowledged,” he said, “This is important for state DOTs because noise impacts of transportation projects on roadside communities have to be quantified and analyzed in order to receive federal funding.”

Other states are looking at ways to more accurately predict the costs of sound mitigation as well – now and in the future.

Iowa, for example, is looking at developing a new noise wall cost GIS-based prediction tool that incorporates residential lot information while ensuring that projects requiring noise abatement are properly planned and funded.

Charles Bernhard, Iowa DOT’s Traffic Noise Engineer, said those new processes include five distinct efforts:

Mapping out five-year highway project plans.

- Eliminating highway projects that do not have an annual average daily traffic or AADT of greater than 10,000.

- Eliminating projects by “work type” that do not meet the definition of a Type I project for noise

- Creating a “parcel layer” that includes all residential parcels within 200 feet of the “edge of pavement” of the remaining highway segments.

- Visually evaluate each remaining highway segment to determine if the segment has a “cluster” of seven or more residential parcels within the 200-foot “buffer.”

Part 2 of this noise abatement series will examine some of the new types of sound wall materials some state DOTs are studying.