The Minnesota Department of Transportation (MnDOT) has utilized the Design–Build (DB) method of project delivery for two decades and has experienced a variety of benefits. MnDOT has also delivered successful projects using the Construction Manager/General Contractor (CM/GC) delivery method since 2013. MnDOT’s experience with DB and other alternative delivery methods offers a comprehensive perspective for the use of alternative delivery on DOT-delivered infrastructure projects.

MnDOT’s Experience with Benefits of Design–Build

MnDOT has varied perspectives on what are considered the common benefits of DB over the traditional Design–Bid–Build (DBB) model:

- Time Savings: MnDOT has experienced time savings using DB over DBB. MnDOT attributes the time savings over DBB due to the ability to commence construction before the full project design is completed.

- Claims and Change Orders: MnDOT has seen a slight reduction in the number of change orders issued in DB compared to DBB. MnDOT believes that DB has the potential to reduce change orders, but has found that there are times when the agency decides to add scope to DB projects that results in owner-directed change orders, narrowing the gap between the quantity of change orders on DB projects compared to DBB. An additional cause for the minimal reduction in change orders may also be the fact that MnDOT uses DB for larger, more complex projects where changes are inherently more likely. Nevertheless, the types of change orders on DB projects can be different than DBB. In particular, the shifting of risks under design–build contracts has reduced claims in certain disciplines where the design– builder is responsible for the risk. For example, MnDOT has seen fewer earthwork claims on DB projects than DBB projects due to shifting the risk of resolving earthwork issues to the design–builder.

- Innovation: MnDOT has found that DB results in greater innovation than DBB, mainly through using Alternative Technical Concepts (ATCs). Several DB highway projects have benefited from innovative approaches to construction methodology incorporated into the project through ATCs.

Environmental Experience

MnDOT typically completes the NEPA process before the release of an RFP, and as a result, has not experienced a significant difference in the environmental processes between DB, DBB, and CM/GC projects. However, MnDOT has found that greater attention may be required for the DB environmental process than DBB since the agency typically uses DB for larger, more complex projects. To date, the agency has had only one DB project that required a NEPA re-evaluation due the implementation of an ATC. Nevertheless, in MnDOT’s opinion, there is a chance that some contractors may not submit ATCs for DB projects due to the risk of a future NEPA re-evaluation. In some cases, the agency will not allow certain ATCs to be submitted if there is a high likelihood that implementation would require an environmental re-evaluation.

Design–Build Selection Factors

MnDOT uses a standard set of factors to guide its decision on project delivery. To undertake this process, the agency brings together several technical discipline experts, including the Project Manager, design, risk, and innovative contracting to discuss risks, cost/schedule, project goals, and what they can accomplish using each delivery option (DBB, DB, CM/ GC). MnDOT will assign ratings in a matrix to reach a preliminary determination of which delivery model (DBB, DB, CM/GC) would be optimal for a project.

The primary drivers for choosing DB are often when a project is considered more complex and where a design–builder is better able to manage the project’s risks. MnDOT tends to use DBB for projects considered straightforward, regardless of the project’s value and size. In addition to procuring DB projects using a best-value methodology, MnDOT also uses a low-bid DB procurement process. MnDOT may use low-bid DB when a project is on an expedited timeline with no other complicating factors. Low-bid DB still offers the opportunity for design–builders to propose ATCs, but the final selection is based entirely on the price rather than a weighted mix between technical and price factors.

CM/GC has grown in popularity with MnDOT in recent years. The agency will consider CM/GC for projects where MnDOT needs or desires to exercise greater control over the design than available under DB, but where contractor input on the design is nevertheless desirable. Another factor favoring CM/GC or DBB instead of DB is the presence of third-party risk that a design–builder is not in the best position to mitigate. A notable example of this is the presence of a third-party stakeholder that might delay environmental approval resulting in schedule uncertainty that is not suitable to DB. Historic bridge projects are an example of this factor that might lead the agency to use CM/GC.

Unique MnDOT Design–Build Factors and Market Appetite

MnDOT has a unique evaluation process for DB and CM/GC projects that involves having a representative from the Associated General Contractors (AGC) participating on the proposal evaluation committee. This is required under Minnesota’s design–build enabling law and MnDOT has adopted the process for CM/GC procurements. Although this was a new concept when MnDOT first implemented it, over time the agency found that the presence of an AGC representative has helped gain trust with the contracting industry.

Lessons Learned Implementing DB

MnDOT staff continue to adapt to managing DB projects. For most DB projects, the agency generally hires outside consultants to assist MnDOT staff through the DB procurement and administration process. The largest change for MnDOT staff shifting toward DB projects has been in the context of providing feedback on the design–builder’s compliance with performance-based specifications, which requires a different perspective than DBB, including the elimination of preferential comments on the design–builder’s design. While MnDOT has found that the agency has better adapted as it delivered more DB projects, the process is a continuous effort and warrants proper staff training on every new DB project.

Critical lessons learned on DB projects include:

- A careful approach to weighting the technical and price proposal scores is important. In earlier DB procurements, the scoring was such that MnDOT could pay a significant premium for a proposal with a higher technical score. To bring a better balance to the best value approach, when preparing the weighting between technical and price proposals, MnDOT assesses the trade-off between a higher technical score and a lower fixed price. This has resulted in a best value approach that more consistently aligns the agency’s desire for a comprehensive technical approach with the need to control costs; and

- Continuity of project staff, particularly the project manager, is critical. MnDOT attempts to assign the project manager as early as possible in the project development process to maximize the ability to convey the project’s intended function through the procurement and delivery of the project.

MnDOT has found that contractors have either been as successful in meeting DBE requirements on DB projects as they are on DBB projects, or that contractors exceed DBE requirements more frequently on DB projects than on DBB projects. MnDOT attributes this to:

- Most DB projects have DBE “meet and greets” with the contractors during the procurement at which

the MnDOT civil rights liaison is able to introduce the potential design–builders to qualified DBEs; - Design-builders have a greater degree of control over the work types and a greater ability to fit DBE

contractors into the projects; and - By also performing the design work, design–builders gain the ability to hire DBE sub-consultants that

counts toward DBE participation goals.

DB Project Example

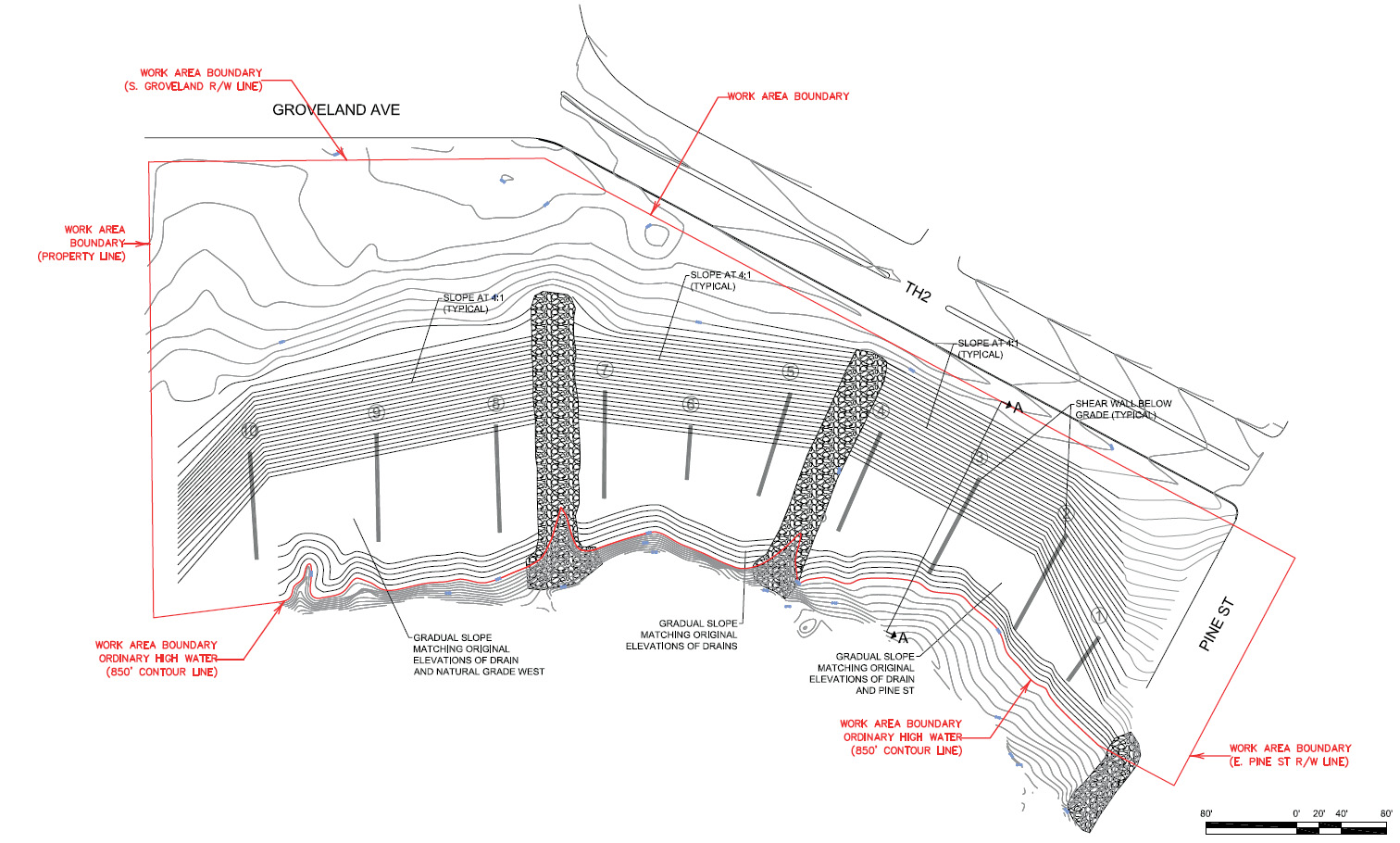

The Crookston Slope project in the City of Crookston, Minnesota, highlights MnDOT’s successful use of DB to obtain diverse, innovative solutions to a complex problem. Years of investigation data showed a worsening, deep-seated slope failure off U.S. Route 2 in Crookston with active slope “creep” closer to the road and historic slides in 1934 and 2008. While the site was well-bounded with few third-party issues, the ideal solution remained unknown prior to this project commencing, offering significant opportunity to gather innovative concepts from design–builders.

MnDOT used DB to procure a contractor to stabilize the slope. Using DB allowed the agency to receive competing designs and multiple concepts from the industry to solve the problem. In addition to design innovation, MnDOT chose DB because it had the potential for warranty risk transfer, shifting risks associated with soil conditions, reducing permitting issues, expediting project initiation, and the highest likelihood of a cost-effective solution. Four design–build teams submitted proposals, each offering their own innovative solution to stabilize the slope. This included installing 700 concrete piling “walls”, soil anchors, deep soil mixing columns or “shear walls”.

The team that proposed installing shear walls was chosen and offered a proposal price 13 percent lower than MnDOT’s engineering estimate. MnDOT considers the Crookston slope project to be a prime example of how DB can benefit DOT highway projects.

Conclusion

MnDOT has experienced success using the DB and CM/GC alternative delivery approaches. The agency plans to continue to use both DB and CM/GC for additional projects in the future. MnDOT will continue to use DBB for relatively straightforward and less complex projects that do not present opportunities for innovation or would not benefit significantly from early contractor involvement. In addition, MnDOT will continue to use low-bid DB procurement to deliver complex projects where necessary.

For further information, please contact: Peter Davich, Design–Build Program Manager, at [email protected].