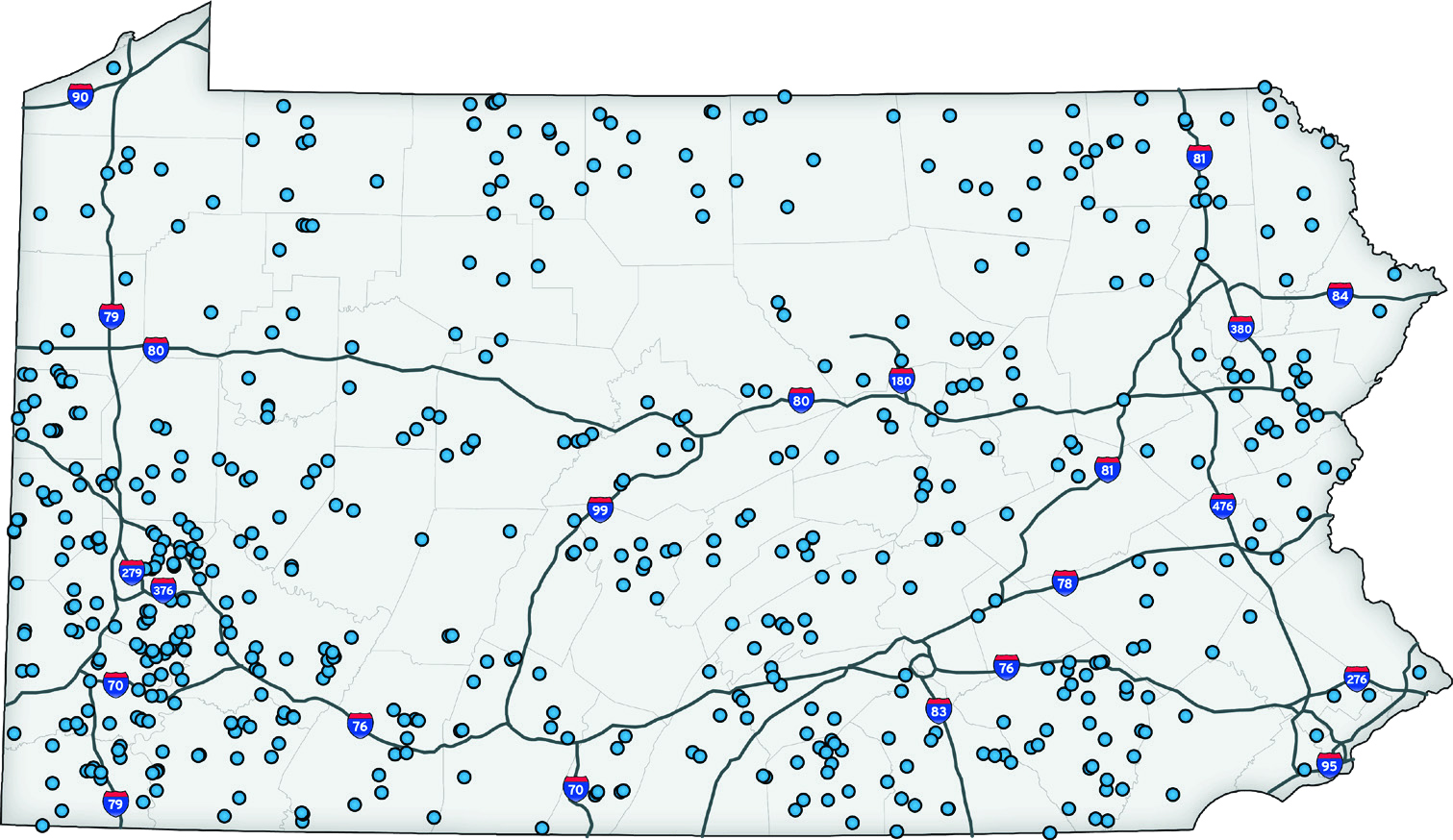

The Pennsylvania Department of Transportation (PennDOT) has utilized the Design–Build (DB) method of project delivery for several highway projects and has experienced a variety of benefits. PennDOT has also recently started to employ the Public–Private Partnership model (P3) to deliver projects. PennDOT recently completed its first significant P3 project, known as the Rapid Bridge Replacement (RBR) project, which bundled hundreds of bridges across PennDOT’s network for full bridge replacements and approach upgrades. A map of the project’s scope is provided below. Overall, PennDOT has found that alternative delivery methods offer significant benefits when used on the right projects.

PennDOT’s Experience with Benefits of Design–Build and P3

PennDOT has varied perspectives on what are considered the common benefits of DB and P3 over the traditional Design–Bid–Build (DBB) model:

- Time Savings: PennDOT has experienced time savings using DB over DBB due to the overlap of design and construction on DB projects. However, PennDOT cautions that this is dependent on the amount of Right of Way acquisition and utility relocation involved for a project, and that complex projects with significant Right of Way and utility needs can experience extended durations and create problems for DB projects. PennDOT experienced significant time savings for the RBR project and believes this was in part attributable to the P3 delivery method. PennDOT believes it would have taken several more years to complete the project using DBB. The bulk of time savings on the RBR P3 project was achieved due to the ability to bundle bridges into a single procurement and contract rather than an individual contract for each bridge. Additionally, using the P3 model allowed for expedited procurement of a single entity acting as the designer and contractor, as well as the ability to have the developer finance construction of the project. This process allowed PennDOT to move forward with the complete project earlier than would have been possible using DBB, while avoiding an impact on funding for PennDOT’s normal letting program.

- Change Orders and Claims: PennDOT has experienced a reduction in overruns and change orders using DB compared to DBB. However, PennDOT receives about the same number of claims on both types of projects, although the nature of the claims in DB is different than DBB. The most substantial DB claims have involved delays in Right of Way acquisition and utility relocations. On the RBR P3 project, PennDOT issued owner-directed change orders adjusting the project scope, but generally experienced fewer contractor-initiated claims compared to a typical DBB project.

- Innovation: PennDOT has found that both DB and its major P3 project brought technical innovations that have ultimately benefited projects.

- Scope Additions: PennDOT has experienced less scope creep on DB and P3 as compared to DBB. On DB projects, PennDOT attributes this to the fact that its DB projects are low-bid procurements. For the RBR P3 project, there was also minimal scope creep since the main asset of this project, bridges, did not leave much room for scope additions.

Environmental Experience

On DB projects, PennDOT typically completes the NEPA process prior to the completion of the conceptual plans. As a result, PennDOT has not experienced any noticeable difference in environmental clearance times between DB and DBB projects. For the RBR P3 project, through a SEP-15 approval from FHWA, PennDOT was able to shift the responsibility for obtaining all NEPA clearance and required permits to the private entity through a special arrangement with FHWA. While the RBR P3 project did experience a NEPA re-evaluation, it did not significantly impact the project schedule.

PennDOT did not experience environmental litigation for the RBR P3 project. Further, in PennDOT’s view, DB and P3 contractors do not hold back proposing Alternative Technical Concepts (ATCs) in alternative delivery projects based on the potential need for an environmental re-evaluation.

Design–Build and P3 Project Selection Factors

PennDOT has found that contractors seem willing and eager to participate in both DB and P3 procurements, but the contracting industry has cautioned PennDOT about the fact that alternative delivery projects can result in contractors assuming additional risks. Despite the risks, industry appetite for alternative delivery projects, especially for the RBR P3 project, was strong, and remains strong for PennDOT’s upcoming P3 projects.

PennDOT considers the following to be the primary factors that warrant using DB over DBB:

- Complex scope of work

- Expedited completion would benefit the project

- Need and potential for innovative solutions through ATCs and unique approaches to design and construction

- Right of Way requirements are either not extensive or can be completed without significant delay

- Utility coordination and railroad impacts are either minimal or can be completed without significant delay

PennDOT considers the following to constitute factors that would support using P3:

- Availability of and need for private funding

- Addressing a serious infrastructure problem sooner

- Using availability payments to pay for the work

- Shifting certain operations and maintenance obligations to a private partner

In contrast, PennDOT continues to use DBB for projects that:

- Have funding in place

- Have little potential or need for innovation

- Require significant or complex Right of Way or utility coordination

- Do not have complex scope

- PennDOT has the internal resources to manage

As of today, PennDOT is not approved to use the CM/GC or CMAR delivery methods. Progressive design-build is currently under consideration.

Lessons Learned Implementing DB and P3

When DB was first introduced to PennDOT, training and guidance from more experienced staff were utilized to help all staff adapt to managing a new delivery model. For the RBR P3 project, PennDOT primarily used outside consultants due to the large scope of the project and the need for external expertise with P3 delivery.

PennDOT’s primary lessons learned from its alternative delivery experience include the following:

- Proper risk allocation between the owner and contractor is necessary;

- Implementing a time management system early in the project avoids later issues;

- Engaging in early discussion concerning expectations and responsibilities between the parties establishes a better working relationship;

- Centralized office locations or co-location requirements facilitate collaboration;

- Creating a comprehensive operational plan that includes a document control system, streamlined review process, and a dispute resolution process can help a project run efficiently;

- Eliminating preferential design comments from the agency can reduce issues; and

- Coordinating activities between stakeholders as early as possible improves relationships during the project.

PennDOT has not experienced a significant difference in contractors’ ability to meet DBE requirements for DB projects compared to DBB projects. The RBR P3 project was successful in meeting DBE requirements. PennDOT attributes this success to a constructive outreach program and early identification of work items that could be assigned to DBE firms, in addition to a comprehensive monitoring program providing oversight of the contractor’s compliance with DBE requirements.

Conclusion

PennDOT has experienced value from DB and P3, and, while benefits for DB are project specific, PennDOT foresees continued use of DB and P3 for future highway projects. PennDOT will continue to use DBB on projects that are relatively straightforward, are generally less complex, and that do not present opportunities for innovation.

PennDOT’s RBR project has proven to be a successful use of the P3 delivery method. Below is a map of the bridges replaced across the state, as well as a photo of one of the completed projects.

For further information, please contact: Mark D. Lombard, Highway Administration Program Manager, Pennsylvania Department of Transportation, at [email protected].